So I've been exploring the "add a brace/stock to a Glock" genre and haven't really been satisfied with what I see out in the market. Like everything else, each company's iteration has its own set of pros/cons. My main gripe is that they are usually specific to one gun and to use them on other pistols and calibers you had to buy a whole different system. Mostly, I was motivated to find something that would work with a PF45. About the only thing I could find was the Mechtech.com system and the thing is super-duper heavy. The Roni-type and Meta tactical systems that engulf the pistol are all ugly plastic nightmares (IMHO) and interfere with some aspects of the slide (optics, suppressor-height sights, etc.). I purchased a Recover Tactical system (with shoulder stock add-on) for my PF940C, because they are fairly cheap. I added a 16" Meta Tactical barrel to keep it legal for adding a stock. The Recover Tactical setup is pretty good, but it rubs against my Holosun leading to poor groups out past 50 yards, so I'm going to have to do some sanding. Plus, that didn't solve my PF45 problem, so I decided to build my own PCC conversion. This is what I came up with......

I need to get a plug to cover the hole at the end of the 30mm carbon fiber tube (above) as I do for the 1" (25mm) tube (below). It gives it a more finished (i.e. less ghetto) look. You'll notice that the 30mm tube that holds the stock offsets to the left of the pistol. I thought I would have to cut it and use another ring setup to bring it back behind the gun. Much to my delight, the setup shoulders perfectly where it is and makes for a great cheek weld and sight picture (iron sights or red dot). Also, I was surprised to learn that the diameter of a buffer tube is almost 30mm, so the lightweight minimalist type of stocks can easily be modified to fit.

Notice the two QD scope rings that attach the 1" carbon fiber rod to the pistol's pic-rail. The farthest one out from the trigger guard doesn't actually sit in a pic. slot, but does clamp the rail (see above and below). I set it up this way so that on my PF45, which has a longer pic-rail, it will have both rings running within the slots. This allows me to switch the system between guns without moving the scope rings. On both pistols, I wanted the 1" tube to butt up against the front of the trigger guard for added rigidity. It's hard to see that above with all of the black-on-black. I have a 10mm barrel on backorder with Meta Tactical.

The front pic-rail works great for a light or a bipod. Below are some pics with it somewhat disassembled. The only connection to the pistol is at its pic-rail, so it's really quick to put on and clamp down with the QD screws. I was worried that the 30mm tube would make accessing the mag release and the slide release difficult. It doesn't if you train to use your off-hand to.... pull the loaded front mag out as you come off of the foregrip, hit the mag release, insert the fresh mag, and then activate the slide release (like hitting the bolt release on an AR). Your firing grip (right hand) and the stock (at the shoulder) can stay in place the entire time.

The whole setup is much more rigid than I thought it would be and is more stable than my Recover Tactical unit. The only flex I can induce is in the PF940C frame itself. If I really pull the thing into my body with maximum tension (like trying to make an offhand 100 yard shot with an AR), I can induce some flex just above where the front of the trigger guard meets the frame of the pistol. That fact is concerning, as I don't want to damage my frame or induce a stoppage during firing. I haven't shot this yet, so I'll have more on that later.

The front magazine holder/vertical grip unit is from Recover Tactical. Meta Tactical makes something similar for 10mm Glock mags.

My whole intent was to explore what's possible with a very lightweight system (see below). You sure as hell won't be battering someone in the head with the buttstock, but who knows...... having something like this in a backpack sure might significantly extend the capabilities of someone whose only weapon on-hand is a pistol. If you had an extra slide with the 16" barrel already installed, one could probably field strip the slide off of a sidearm and have this out of a pack and installed in under 30 seconds. Anyway, just a range-toy and tinkering project for now.

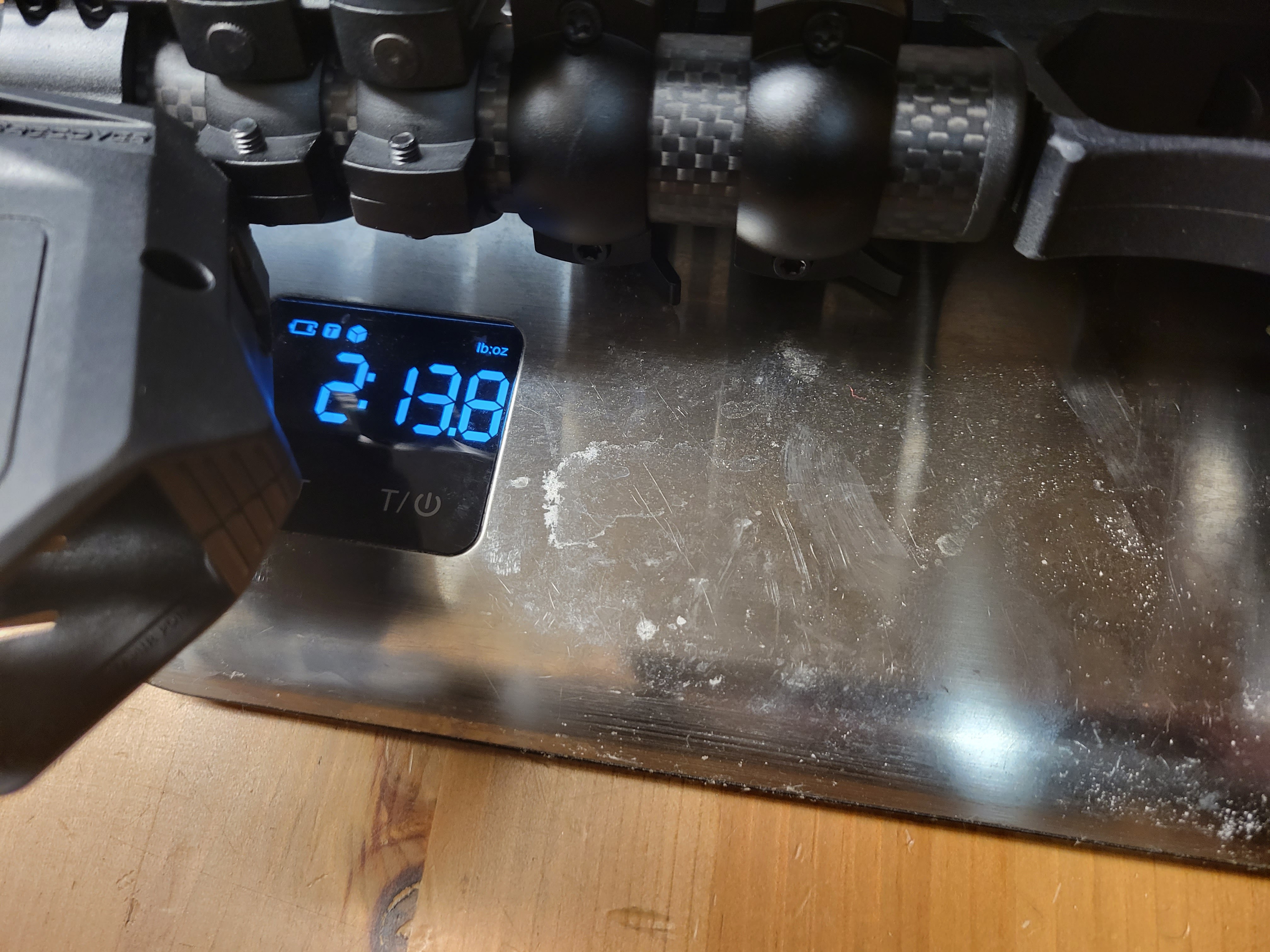

This (above) is the total weight (pistol included) with the light (not bipod) installed and without magazines. I'm sure there's a way to design this to fold or telescope, but that will likely induce some flex. Also, a trigger cover/holster will be a necessary safety item to add.

Cost wasn't really the main goal here but money always matters. If it weren't for the barrel, this would be an inexpensive endeavor, but then it wouldn't be legal without a tax stamp because it would be an SBR. If I wanted to SBR it, I would go with a threaded barrel and add either a fake suppressor or a long blast can to keep the forward hand safer. It would make for a nifty compact unit. The various rings, carbon-fiber tubes, and end plugs are all from Amazon and come to about $100. The front grip from Recover tactical seemed expensive at $50 and the ones from Meta Tactical are the same price. I think the stock was about $30 - $40.

My accuracy goal for this project isn't stringent. Since the barrel isn't fixed and the optic isn't magnified I would hope that I can get 4-6 moa out of it, which at 50 and 100 yards is much better than I can shoot with a pistol, but I won't know until I get it to the range over the next couple of weeks. I'll post an update then. Please let me know if you have any suggestions.

I need to get a plug to cover the hole at the end of the 30mm carbon fiber tube (above) as I do for the 1" (25mm) tube (below). It gives it a more finished (i.e. less ghetto) look. You'll notice that the 30mm tube that holds the stock offsets to the left of the pistol. I thought I would have to cut it and use another ring setup to bring it back behind the gun. Much to my delight, the setup shoulders perfectly where it is and makes for a great cheek weld and sight picture (iron sights or red dot). Also, I was surprised to learn that the diameter of a buffer tube is almost 30mm, so the lightweight minimalist type of stocks can easily be modified to fit.

Notice the two QD scope rings that attach the 1" carbon fiber rod to the pistol's pic-rail. The farthest one out from the trigger guard doesn't actually sit in a pic. slot, but does clamp the rail (see above and below). I set it up this way so that on my PF45, which has a longer pic-rail, it will have both rings running within the slots. This allows me to switch the system between guns without moving the scope rings. On both pistols, I wanted the 1" tube to butt up against the front of the trigger guard for added rigidity. It's hard to see that above with all of the black-on-black. I have a 10mm barrel on backorder with Meta Tactical.

The front pic-rail works great for a light or a bipod. Below are some pics with it somewhat disassembled. The only connection to the pistol is at its pic-rail, so it's really quick to put on and clamp down with the QD screws. I was worried that the 30mm tube would make accessing the mag release and the slide release difficult. It doesn't if you train to use your off-hand to.... pull the loaded front mag out as you come off of the foregrip, hit the mag release, insert the fresh mag, and then activate the slide release (like hitting the bolt release on an AR). Your firing grip (right hand) and the stock (at the shoulder) can stay in place the entire time.

The whole setup is much more rigid than I thought it would be and is more stable than my Recover Tactical unit. The only flex I can induce is in the PF940C frame itself. If I really pull the thing into my body with maximum tension (like trying to make an offhand 100 yard shot with an AR), I can induce some flex just above where the front of the trigger guard meets the frame of the pistol. That fact is concerning, as I don't want to damage my frame or induce a stoppage during firing. I haven't shot this yet, so I'll have more on that later.

The front magazine holder/vertical grip unit is from Recover Tactical. Meta Tactical makes something similar for 10mm Glock mags.

My whole intent was to explore what's possible with a very lightweight system (see below). You sure as hell won't be battering someone in the head with the buttstock, but who knows...... having something like this in a backpack sure might significantly extend the capabilities of someone whose only weapon on-hand is a pistol. If you had an extra slide with the 16" barrel already installed, one could probably field strip the slide off of a sidearm and have this out of a pack and installed in under 30 seconds. Anyway, just a range-toy and tinkering project for now.

This (above) is the total weight (pistol included) with the light (not bipod) installed and without magazines. I'm sure there's a way to design this to fold or telescope, but that will likely induce some flex. Also, a trigger cover/holster will be a necessary safety item to add.

Cost wasn't really the main goal here but money always matters. If it weren't for the barrel, this would be an inexpensive endeavor, but then it wouldn't be legal without a tax stamp because it would be an SBR. If I wanted to SBR it, I would go with a threaded barrel and add either a fake suppressor or a long blast can to keep the forward hand safer. It would make for a nifty compact unit. The various rings, carbon-fiber tubes, and end plugs are all from Amazon and come to about $100. The front grip from Recover tactical seemed expensive at $50 and the ones from Meta Tactical are the same price. I think the stock was about $30 - $40.

My accuracy goal for this project isn't stringent. Since the barrel isn't fixed and the optic isn't magnified I would hope that I can get 4-6 moa out of it, which at 50 and 100 yards is much better than I can shoot with a pistol, but I won't know until I get it to the range over the next couple of weeks. I'll post an update then. Please let me know if you have any suggestions.

Last edited: