I could be wrong but I think ported barrel is increasing slide velocity where the slide RSA insert part is hitting RSA walls.

Errr, no. Sorry, not the issue.

@Racer88 is correct, all else equal (Recoil Spring-weight, Guide Rod type, slide weight, and especially the ammo itself, a Ported barrel will yield LESS energy available to cycle the slide rearward. Therefore, the slide will have LESS kinetic energy (velocity) with which to strike the frame at the stops ("Posts").

The problem is almost certainly the slide itself, in this case. As the 'windowed' and 'lightened' and 'ported' slides begin to lose mass, by virtue of the material being machined off of the 'blank', the energy transmitted into it via the ammunition's reactionary force is not 'absorbed' by the heavy slide, and with all else being equal, the same amount of energy pushing the slide rearward WILL result in a faster slide action. This transmits MORE (not less) energy into the frame-stops, gives the Recoil Spring LESS time to slow the slide's action, and may very well cause the damage you are seeing. The best thing to do is weigh the windowed/lightened/ported slide vs a comparable-model Glock slide, to determine how much percentage of the slide's mass (as engineered) has been removed.* This can help you to determine if stepping-up the Recoil Spring weight may be necessary... Which gets complicated when then adding a Ported barrel, which LOSES energy more rapidly, and you may end up in a corner with too much Recoil Spring, and too little reactive force to reliably cycle a slide that is made too light. Fortunately, Glocks (and their clones) are over-simplified, and offer a very wide functionality range.

*In this picture, you can see that Glock has engineered different 'weights' to their slides, it is all a balancing-act to get the most reliable, highest performing 'action' from their designs, able to use the widest possible loads of ammunition for any given caliber, without allowing the slide to beat the frame to death in the process. This is a 9mm vs 40-cal, yes also Gen 3 vs Gen 4, which also have dramatically different RSA characteristics, but this still illustrates my point:

IF more troubles are seen with Ported barrels REGARDLESS of slide-weight however, and I find it unlikely, then I would consider the added TEMPERATURE within the firearm caused by Porting the barrel, especially on aftermarket barrels that may have issues expelling the Ported gasses at a high enough velocity -configurations that often leave excessive carbon build-up in the channel area. This additional heat COULD theoretically reduce the tensile strength of the frame's polymer, leaving it 'soft' and malleable..

A good solution without hunting through a stack of Goldilocks-seeking Spring-Weights (

this one is Just Right!) is to use a recoil 'cushion', similar to what you are doing with the metal insert, but very much in the opposite direction -soft cushioning rubber or silicon instead. Most likely, that steel insert will eventually deform, leading to reliability problems, or continue to damage the frame, or in all likelihood will eventually damage the slide itself. The rubber cushions are already on the market, I have seen them for VERY cheap, if you buy a lot of them, and they are fast and easy to install. I just keep forgetting to actually get any for testing... [Sigh].

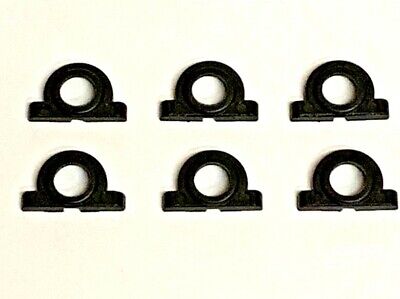

Edit: here is an example of a harder poly variant, under $1 each in a six-pack, I also found 12-packs at under 50-cents per buffer: Search for "Glock Buffer" or "Glock Recoil Buffer"

This buffer is made out of a durable polyurethane material, and is easily installed between the recoil spring guide and the end of the slide. This part is to be replaced every 1,000 rounds.

www.ebay.com