- Joined

- Jun 19, 2022

- Messages

- 954

- Reaction score

- 1,386

- Points

- 108

Little update. It's not been a good week. On other issues, my flock of chickens were decimated by someone's loose dog that found it's way to the farm.

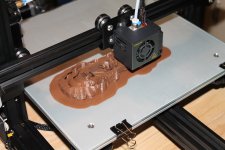

3D printing also had some setbacks. The Fusionworks PLA+ "skin" colored material is more like a soft plastic. A real pita to print with. I haven't had a successful print with it yet. Bed adhesion issues and the material is kinda rubbery after printing. Ended up ordering a roll of eSun PLA+ in matte brown to try this again.

Meanwhile, the jig for the JDS P320 MUP showed up. MUP itself hasn't made the scene yet, even though it was ordered a few days before the jig.

3D printing also had some setbacks. The Fusionworks PLA+ "skin" colored material is more like a soft plastic. A real pita to print with. I haven't had a successful print with it yet. Bed adhesion issues and the material is kinda rubbery after printing. Ended up ordering a roll of eSun PLA+ in matte brown to try this again.

Meanwhile, the jig for the JDS P320 MUP showed up. MUP itself hasn't made the scene yet, even though it was ordered a few days before the jig.