- Joined

- Jun 19, 2022

- Messages

- 950

- Reaction score

- 1,381

- Points

- 108

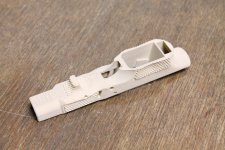

Dozed off and missed the point where the filament ran out. Printer just flagged the error and parked the head in the corner of the bed. It got as far as the trigger guard, so it is a success for my purposes. Took about an hour to clean off all the excess supports. And for the purposes of taking pictures, it got a quick coat of flat brown paint.

Now to twiddle my thumbs for a few days and wait for parts & more filament to show up.

Now to twiddle my thumbs for a few days and wait for parts & more filament to show up.