- Joined

- Nov 12, 2022

- Messages

- 143

- Reaction score

- 68

- Points

- 28

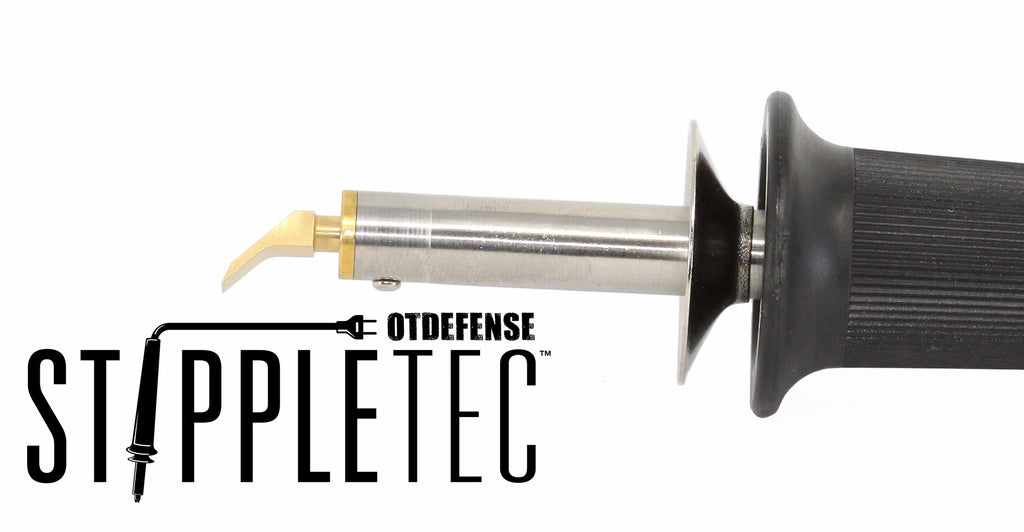

I got a wood burner (25watt) and some tips to try my hand at stippling. I work with plastic on a lot of varied hobbies so this seemed like a cool idea to bring some skills used in the gun world to other places too.

I found the skill to be fairly easy to pick up except one thing: if the plastic isn’t black colored, you see burned material! So you end up with, say, a blue piece of plastic where all the high points are black. Not a good look IMO.

For those that stipple, how do you avoid this?

The only way I have found is to wipe the tip after each press as it’s more plastic staying on the tip and burning than it is burns from the actual press. However, this is obviously not a great answer as it drastically increases the time required.

I have seen videos online of guys doing colored stipple work where they even are dragging the tip along to do a pattern, so it must be doable. But these have all been soldering irons (which often include temp controls), so that may be their trick?

If that’s the key, has anyone ever used a variable voltage regulator on a wood burner to create a temp control?

Any help would be great as my use case likely won’t include a lot of black plastic.

I found the skill to be fairly easy to pick up except one thing: if the plastic isn’t black colored, you see burned material! So you end up with, say, a blue piece of plastic where all the high points are black. Not a good look IMO.

For those that stipple, how do you avoid this?

The only way I have found is to wipe the tip after each press as it’s more plastic staying on the tip and burning than it is burns from the actual press. However, this is obviously not a great answer as it drastically increases the time required.

I have seen videos online of guys doing colored stipple work where they even are dragging the tip along to do a pattern, so it must be doable. But these have all been soldering irons (which often include temp controls), so that may be their trick?

If that’s the key, has anyone ever used a variable voltage regulator on a wood burner to create a temp control?

Any help would be great as my use case likely won’t include a lot of black plastic.