I've been working on a new "EDC" in the form of a build based on a 100% serialized frame. My first order of business was to make sure it functioned reliably with FMJ range ammo. No problems there, with 1,000 rounds of common 115-gr FMJ over several range trips. During the last range trip, I tried some defensive hollow point ammo. For the first test, I ran through 20 rounds of Federal HST +P 147-gr. That is the defensive ammo I've had in my factory Glock 19 for years. It fired flawlessly in the P80 EDC build. And it was time to go home at that point.

Today I had a combination of tasks. I added an optic. So I needed to get that zeroed. I also wanted to continue reliability testing with both FMJ and HP ammo. The weight of an optic on the slide can potentially cause issues.

![20220929_165235[1].jpg 20220929_165235[1].jpg](https://www.patriotgunbuilders.com/forums/attachments/20220929_165235-1-jpg.6345/)

The optic zeroing and testing went very well.

I got some new 124-gr FMJ ammo to try, and it proved to be reliable with the optic installed.

![20220930_105614[1].jpg 20220930_105614[1].jpg](https://www.patriotgunbuilders.com/forums/attachments/20220930_105614-1-jpg.6346/)

I had also recently purchased some Federal HST 124-gr hollow points to test in addition to my existing stash of HST +P 147-gr. I ran 25 rounds of the new HST 124-gr ammo through with zero malfunctions. I forgot to bring a box of the HST +P 147-gr ammo. But then I remembered I had some in my pocket, in my spare mag for my current EDC - a Gen 2 Factory Glock 19. I popped the spare mag in my P80 EDC build and fired 9 rounds. Zero problems. I decided that was enough for now, and I didn't want to "waste" the rest of the ammo in that mag. I dropped the mag and went to manually eject the live round in the chamber.

Rut-roh! The slide wouldn't rack! It was stuck! I mean it would not BUDGE... at all. It felt like it was glued shut! Surely my eyes and hands deceive me. This can't be happening with my "perfect build!" I kept the muzzle pointed down range and tried to rack the slide again. No dice! REALLY?!?? WTF?!?? Tried AGAIN with some real force. NOPE! I'm pretty sure I heard my gun laughing at me!

Naturally, we test defensive ammo compatibility by loading and FIRING it. Usually all of it - whatever we loaded in the magazine. Checking accuracy - POA = POI. Checking reliability in terms of feed, fire, extraction / ejection. We don't want to find out the ammo causes problems when the SHTF. One of the most common issues with Hollow Point ammo is Failure To Feed (FTF). The truncated shape of hollow points may not play well with the barrel feed ramp in some cases.

But, what about manually cycling live rounds without firing them? Manually extracting live rounds? We do it with Snap-Caps during function testing at home. But, I will admit it had not occurred to me to test it with live ammo. But by chance at the range, I tried... and failed.

Finally, I decided to just fire that stuck round (without the mag) and see what happens. Bang and a perfect extraction and ejection of the spent shell. What gives??? It occurred to me that perhaps the 147-gr bullet in the HST +P round is slightly longer, and maybe that's why it was stuck when I tried to manually eject the live round. Time to go home and do some analysis!

I went home. I loaded a mag of regular HST 124-gr ammo and manually cycled it. Like buttah! No problems. I loaded some HST +P 147-gr ammo. Chambered the first round. It fed without a problem. Then I tried to eject it. Problem! Jammed again. I tried again with more force. Jammed!! I tried again using MORE force. Success! It took a surprising amount of force to get the round to eject. What is up with that?? No bueno!

Time for more analysis. "Plunk" test time! The Plunk Test involves removing the barrel and dropping a live round into the chamber. It should drop in easily. You should be able to rotate / spin the round in the chamber easily. And when you turn the barrel chamber-down, the round should drop out.

I compared CCI FMJ 124-gr, Federal HST 124-gr, and problematic Federal HST +P 147-gr. The CCI FMJ and HST 124-gr passed the plunk test easily. However, the HST +P 147-gr.... was what I will call "sticky." If I pressed the round into the chamber, I could turn the barrel upside down and the round would stay in the chamber. Interesting.

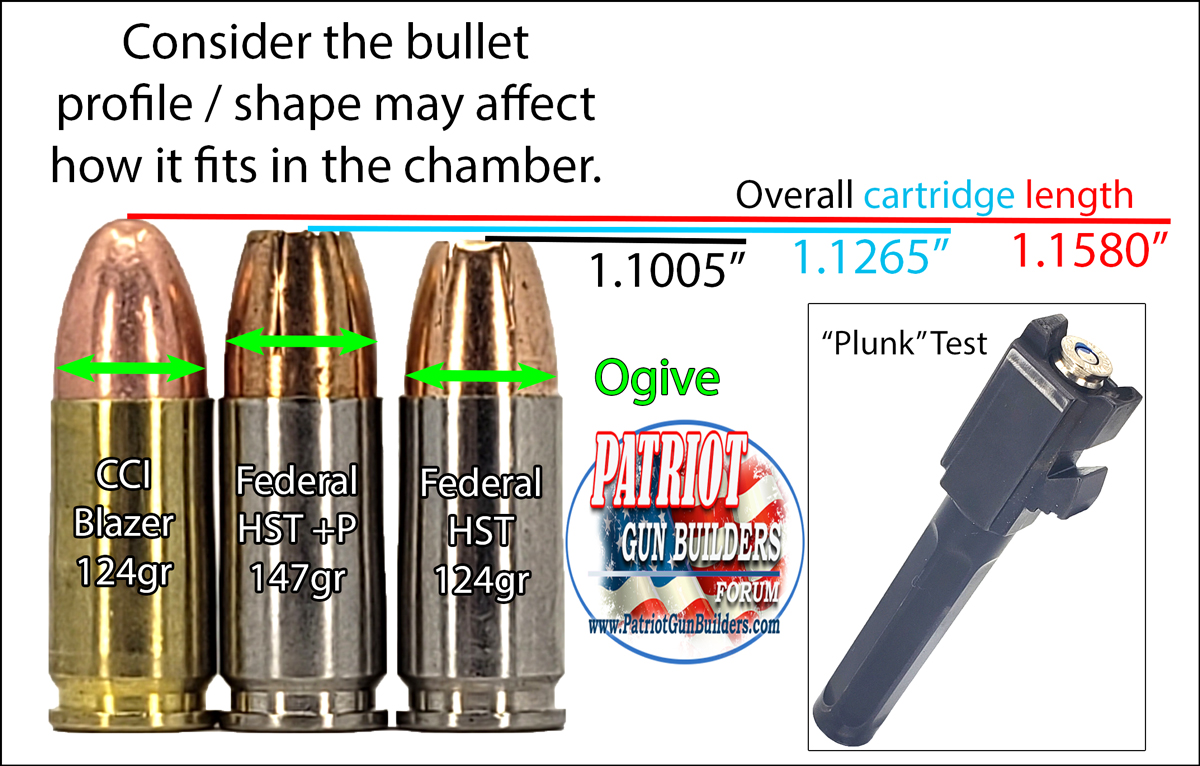

Next... Let's get out the digital calipers. I measured the same three rounds - CCI FMJ vs HST 124-gr vs HST +P 147-gr. I made this infographic to demonstrate the differences in length and shape between the three rounds:

While the HST +P 147-gr is longer than the HST 124-gr, I realized that it couldn't just be the length causing the issue. The CCI FMJ 124-gr ammo was longer than both of them. But, look at the bullet profiles. The FMJ is nearly conical, as is most 9-mm FMJ ammo. The HST 124-gr ammo is fairly tapered, as well. But, you can see that the HST +P 147-gr has a side profile that is straighter... more parallel... not as tapered. Perhaps this is causing the problem with manually cycling / extraction of the live rounds.

The take home message....

Test your defensive carry ammo! Whether your EDC or Home Defense gun is a factory firearm or a PMF (personally made firearm).

Test it in every way. When I previously tested the HP ammo, I fired every round I loaded in the magazine. It was "by chance" today that I decided to stop halfway through a mag and unload the gun. That's how I discovered the issue with the HST +P 147-gr round.

What say you? Comment below!

Today I had a combination of tasks. I added an optic. So I needed to get that zeroed. I also wanted to continue reliability testing with both FMJ and HP ammo. The weight of an optic on the slide can potentially cause issues.

The optic zeroing and testing went very well.

I got some new 124-gr FMJ ammo to try, and it proved to be reliable with the optic installed.

I had also recently purchased some Federal HST 124-gr hollow points to test in addition to my existing stash of HST +P 147-gr. I ran 25 rounds of the new HST 124-gr ammo through with zero malfunctions. I forgot to bring a box of the HST +P 147-gr ammo. But then I remembered I had some in my pocket, in my spare mag for my current EDC - a Gen 2 Factory Glock 19. I popped the spare mag in my P80 EDC build and fired 9 rounds. Zero problems. I decided that was enough for now, and I didn't want to "waste" the rest of the ammo in that mag. I dropped the mag and went to manually eject the live round in the chamber.

Rut-roh! The slide wouldn't rack! It was stuck! I mean it would not BUDGE... at all. It felt like it was glued shut! Surely my eyes and hands deceive me. This can't be happening with my "perfect build!" I kept the muzzle pointed down range and tried to rack the slide again. No dice! REALLY?!?? WTF?!?? Tried AGAIN with some real force. NOPE! I'm pretty sure I heard my gun laughing at me!

Naturally, we test defensive ammo compatibility by loading and FIRING it. Usually all of it - whatever we loaded in the magazine. Checking accuracy - POA = POI. Checking reliability in terms of feed, fire, extraction / ejection. We don't want to find out the ammo causes problems when the SHTF. One of the most common issues with Hollow Point ammo is Failure To Feed (FTF). The truncated shape of hollow points may not play well with the barrel feed ramp in some cases.

But, what about manually cycling live rounds without firing them? Manually extracting live rounds? We do it with Snap-Caps during function testing at home. But, I will admit it had not occurred to me to test it with live ammo. But by chance at the range, I tried... and failed.

Finally, I decided to just fire that stuck round (without the mag) and see what happens. Bang and a perfect extraction and ejection of the spent shell. What gives??? It occurred to me that perhaps the 147-gr bullet in the HST +P round is slightly longer, and maybe that's why it was stuck when I tried to manually eject the live round. Time to go home and do some analysis!

I went home. I loaded a mag of regular HST 124-gr ammo and manually cycled it. Like buttah! No problems. I loaded some HST +P 147-gr ammo. Chambered the first round. It fed without a problem. Then I tried to eject it. Problem! Jammed again. I tried again with more force. Jammed!! I tried again using MORE force. Success! It took a surprising amount of force to get the round to eject. What is up with that?? No bueno!

Time for more analysis. "Plunk" test time! The Plunk Test involves removing the barrel and dropping a live round into the chamber. It should drop in easily. You should be able to rotate / spin the round in the chamber easily. And when you turn the barrel chamber-down, the round should drop out.

I compared CCI FMJ 124-gr, Federal HST 124-gr, and problematic Federal HST +P 147-gr. The CCI FMJ and HST 124-gr passed the plunk test easily. However, the HST +P 147-gr.... was what I will call "sticky." If I pressed the round into the chamber, I could turn the barrel upside down and the round would stay in the chamber. Interesting.

Next... Let's get out the digital calipers. I measured the same three rounds - CCI FMJ vs HST 124-gr vs HST +P 147-gr. I made this infographic to demonstrate the differences in length and shape between the three rounds:

While the HST +P 147-gr is longer than the HST 124-gr, I realized that it couldn't just be the length causing the issue. The CCI FMJ 124-gr ammo was longer than both of them. But, look at the bullet profiles. The FMJ is nearly conical, as is most 9-mm FMJ ammo. The HST 124-gr ammo is fairly tapered, as well. But, you can see that the HST +P 147-gr has a side profile that is straighter... more parallel... not as tapered. Perhaps this is causing the problem with manually cycling / extraction of the live rounds.

The take home message....

Test your defensive carry ammo! Whether your EDC or Home Defense gun is a factory firearm or a PMF (personally made firearm).

Test it in every way. When I previously tested the HP ammo, I fired every round I loaded in the magazine. It was "by chance" today that I decided to stop halfway through a mag and unload the gun. That's how I discovered the issue with the HST +P 147-gr round.

What say you? Comment below!

Last edited: